Space Rescue is a leading Australian supplier of Storage Compactors for office and warehouse applications. This is a unique movable shelving system that provides a very space-efficient and high-density means for filing and storage. They are also often referred to as a compactus unit. Instead of many aisles between rows of shelving, this clever design requires only one access space to service all of the shelving bays. In summary, it is just shelving on wheels that run along guide tracks. We deliver and install storage compactors in Sydney NSW, Melbourne VIC, Brisbane QLD, Adelaide SA, Perth WA, and many regional areas.

1. Dimensions and Sizes

Several different heights, bay widths, and shelf depths are available in our Storage Compactor range.

a) Height

Typically, the height of the compactor between 1800mm and 2400mm, with 2175mm being the most common. In saying that, we are able to supply frames at almost any height.

Standard Heights:

- 1950mm

- 2250mm

- 2450mm

It is necessary to fix the top and bottom shelves in place with a nut and bolt. This provides rigidity for the bay. Supporting the intermediate shelves on clips provides the necessary means for shelf adjustment on a slotted side frame.

After the number of shelves per bay has been chosen, the average clear vertical shelf height can be calculated.

b) Depth

The length of the shelf determines the depth of this compactor shelving system (from the front to the rear), with 900mm and 1200mm being the most common, plus 750mm and 1000mm are also available. Achieving a greater unit depth is possible by connecting shelves end-to-end through a common side panel. For example, a unit depth of 1800mm is made up of 900mm plus 900mm shelves joined end to end.

Standard Shelf Lengths:

- 750mm

- 900mm (very common)

- 1000mm

- 1200mm (common)

c) Length

The Storage Compactor length is determined by combining the single-sided and back-to-back stack lengths plus the aisle space. In principle, the sum of these lengths is equal to the track length. The depth of the shelves, typically between 300 and 600mm, determines the width of each stack. An aisle of at least 600mm to 700mm is most common.

Standard Shelf Depths:

- 300mm

- 400mm

- 450mm

- 600mm

2. Drive Type: Handle or Wheel?

A simple handle is the most common means for moving smaller compactor shelving units of single bay depth. For deeper, larger and heavier storage compactors, a wheel-drive (i.e., a mechanically assisted drive) is often used.

a) Limitations with Handle Drive

The limitation with long or deep bay configurations is the movement of the resulting weight of the multiple bay stacks. Deeper and heavier units often require some form of mechanical advantage to make them practicable.

Here is a 6-bay compactor with a handle drive. The open bay shown has six storage levels, or five adjustable shelves resting on shelf clips. The top and bottom shelves are bolted in place.

b) Wheel Drive Workings

The ”mechanically assisted drive” consists of a ”drive wheel” (that is turned by hand), a pair of “drive sprockets,” and a “drive chain” (connecting the drive wheel to the drive sprocket). A more expensive alternative to the manual handle and wheel drive systems is the electric drive (or e-drive). The E-drive consists of an electric motor with keypad controls.

c) Conversion from Handle Drive to Wheel Drive

It is relatively easy to convert your ‘handle’-driven compactor to ‘wheel’-drive. We simply need to change the front track that the unit runs on and add the wheel-drive consoles. Alternatively, we can supply this front ‘wheel drive’ track with your ‘handle drive’ unit to make it less expensive to convert at a later date if you choose to do so.

3. Why are storage compactors efficient with space?

Overview

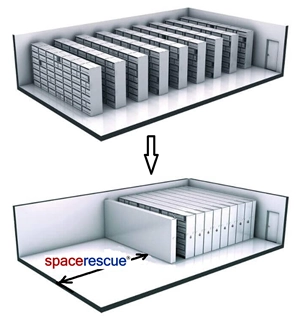

The comparison of the two examples below provides a good visual explanation for this question. The first picture shows nine back-to-back runs of steel shelving with ten pathway spaces between these shelving runs. The second picture shows a large shelving compactor with an equivalent amount of storage and only one pathway space. The removal of nine open pathways frees up a huge amount of space.

Pictorial Explanation

In detail, the steel shelving picture (upper) shows nine (9) back-to-back shelving runs, each seven (7) bays long. This equates to 14 bays per back-to-back shelving run, or 126 bays in total.

To explain, the storage compactor picture (lower) shows two (2) single-sided stacks at each end and eight (8) back-to-back shelving stacks. This also amounts to a total of 126 bays.

The Analysis

Let us assume that the footprint taken up by a back-to-back shelving static run (or movable stack) has the same ‘footprint area’ as the pathway space. Therefore, in the steel shelving picture, there are 9 x shelving ‘footprint areas’ and 10 x aisle ‘footprint areas’. This means there are a total of 19 x ‘footprint areas’ in the steel shelving.

On the other hand, the compactor shelving unit has 9 x shelving ‘footprint areas’ (= 2 x single-sided + 8 x back-to-back) and 1 x pathway space ‘footprint area’. Thus, there is a total of 10 x ‘footprint areas’ in the compactor storage system.

Impressive Result

Comparing the two, we can see that we have gone from 19 x ‘footprint areas’ to 10 x ‘footprint areas’. This represents a saving in space of 47.4%. This is quite dramatic!

4. Accessories for Filing Compactors

It is very common for compactors to be used for filing applications. Below is a list of accessories that are often included when these movable shelving units are used for the storage of files.

a) Cover panels

Cover panels are an aesthetic accessory. They are a panel that is fitted to the outside of the uprights on the front side of the storage compactor. The upright has a series of holes within it that run vertically. While the holes are unsightly, they are necessary for supporting the shelves via small nuts & bolts or shelf support clips. Cover panels provide the option of concealing the perforated upright behind a clean, flat panel. To illustrate this, here are some pictures showing compactors without cover panels.

b) Pull-Out Filing Shelf

The pull-out filing shelf is a handy accessory that enables you to rest and review files on it while still within the compactor shelving unit. They save you from taking files outside of the unit to a desk to review.

5. Summary of the space-saving explanation

a) Benefits of this style of shelving

The benefits of this style of shelving are that you are able to fit more shelving into a space than if you were to use a conventional static shelving system. Compactor shelving is a dense storage system that enables you to do more with the space you have. Ideal in most environments where space is at a premium.

b) It’s to do with the aisle space saved.

You may ask, How is it possible to save so much space? With a static shelving system, if you lined up static shelving stacks with an aisle between each, the overall system length would include all of the individual shelving stack depths plus all of the aisle widths between each shelving stack.

c) Here is how you rescue the space.

Now, if the shelving stacks were movable, you could essentially place each stack directly adjacent to the others, and when you needed to access a particular stack, you would simply create an aisle opening between the two stacks you needed to access. In essence, this saves a number of aisle spaces, as this dense storage system only requires one aisle space.

6. Configuring a Storage Compactor

Firstly, the most common configuration is to have two single-sided bays at either end, with one being static and the other movable.

In between these bays, you will commonly find a combination of movable back-to-back and movable single-sided bays. You may choose to have the end single-sided static bay on the left or right-hand side, depending upon the floor layout.

Closing the compactor unit will expose floor tracks at one end. Hence, the exposed floor tracks will be at the end that has the single-sided end movable bay.

Generally, it is wise to have the movable end away from a high-foot traffic area so the tracks do not pose a trip hazard.

7. Explanation of Other Terms

a) RUT Shelving

To explain, traditional compactor shelving is simply RUT shelving (or steel shelving) with runners and tracks. That is why there is an increase in the overall height from a standard RUT shelving frame height as an additional 75mm is gained due to the runner and track.

b) Movable Shelving

A movable shelving system is exactly what its name suggests. Its shelving is movable. Similarly, static shelving is fixed in place or stationary. Interestingly, the term storage compactor describes a steel shelving system that has a combination of both movable and static shelving bays.

c) Lateral Compactors

Another style of shelving system exists for very narrow spaces where security is not such an issue. By comparison, open bays of shelving face outwards towards the aisle. It consists of a line of movable shelving bays that sit in front of a line of stationary shelves. Sliding the front movable bays from side to side is necessary to create a clear space and provide access to the rear line of static shelving units. Another term given to this style of shelving is lateral storage compactor, or side-to-side compactor.

d) Longspan Shelving Compactors

It is also possible to create a storage compactor out of longspan shelving by attaching the frames to runners. Unlike traditional compactors, movable longspan shelving systems do not require back-to-back bays for the internal movable stacks. These stacks can simply be made wider (i.e., with deeper shelves) so that the single wide shelf depth is accessed by reaching in up to half the depth on either side. As a result, this provides a significant saving on materials.

e) Coolroom Compactors

In wet, cool, and sterile environments, such as coolrooms and medical storage rooms, where the floors are often hosed down or cleaned, the standard floor based runner and track system will struggle. Furthermore, the standard steel shelves will not be ideal. In these applications, it is more practical to use a purpose-designed Coolroom movable shelving unit that is suitable for cold and/or wet conditions.

8. Thoughts on Storage Compactors

a) Why is compactor shelving still the ultimate in space-saving?

When you have a bookcase, you need one aisle space in front of it to enable you to gain access to it. On the other hand, with a storage compactor, you can access multiple bookcases with just one aisle, meaning you can fit more bookcases in one area. There is no limit to the number of bookcases if you have a large area, as long as you leave space for just one space for access. The trick behind this is to put these bookcases on wheels so that you can move the aisle to the bookcase you need access to.

b) Why are compactors so versatile?

Compactor storage systems are particularly versatile as they are modular in design. As a result, filling the available footprint is as easy as using different-sized modules. You will be able to fill up an area as the modularity of the shelving design enables it to be replicated in both length and depth. There are a number of standard heights, lengths, and widths for each module (or bay) to enable you to maximise the space that you have available.

9. Similar Products to Storage Compactors

You may also be interested in our steel workbenches?