A cantilever racking system is the ideal structure for the storage of long, bulky, and heavy-duty products. The main elements of this structure are the vertical columns (or posts), bases, bracing, and horizontal arms. Space Rescue has both single-sided and double-sided cantilever racking for sale in Brisbane, Sydney, Melbourne, Adelaide, and Perth.

1. What is cantilever racking?

A cantilever rack employs horizontal arms attached to vertical columns, extending out to create multiple support levels. Bolting anchored bases to the columns prevents front-to-back movement, while fixing bracing between columns prevents side-to-side (also known as down-aisle) movement.

This structure does not require a front supporting post, as you will see in pallet racking. As a result, access to the arm storage levels is open and unobstructed for the easy placement and retrieval of lengthy items.

In particular, other terms commonly used are cantilever shelving, canti racking, and pipe racking.

2. Summary of sizes

Columns: 2m, 2.4m, 3m, 3.6m, 4.2m, 4.8m, 5.4m, and 6m (heights)

Arms: 700mm, 900mm, 1200mm, and 1500mm (lengths) and 260kg, 350kg, 450kg, 1000kg, and 1300kg (maximum U.D.L.) per single arm.

Bases: lengths vary depending on arm length and whether single or double-sided.

Bracing: 900mm, 1200mm, 1500mm, 1800mm, 2100mm (column centres created)

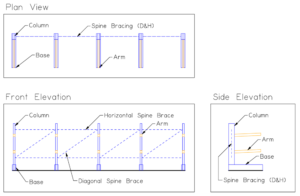

3. Cantilever Racking Plan and Elevation Design

Below is an example of a single-sided cantilever racking plan view, plus both front and side elevation design drawings showing labelled columns, bases, arms, and spine bracing components.

4. Specifications

a) Columns used in cantilever racking

Undoubtedly, columns are an integral part of a cantilever warehouse racking structure. Furthermore, as the name suggests, they stand vertically. They maintain their upright orientation with the aid of a solid bolted connection to the column base and column bracing. A steel pin connects the cantilever rack arms to the columns.

Heights (mm)

- 2000mm

- 2400mm

- 3000mm

- 3600mm

- 4200mm

- 4800mm

- 5400mm

- 6000mm

Depths (mm)

- 200mm

- 305mm

- 350mm

- 410mm

Finish

Blue enamel powder-coat paint finish to the cantilever shelving columns

Manufacturing

Coil steel passes through a rollformer to make the columns, forming the steel into the required section shapes while cold, hence the name cold-rolled steel sections. Furthermore, a series of holes punched up each side of the column provides adjustability for arm positions.

b) Arms used to create cantilever shelving levels

Arms attach to the columns and play a rather important part of the metal cantilever rack structure. Of course, a series or group of arms in close proximity to one another and on the same level create an individual cantilever shelf for products to lay on. You can store almost any length of product by initially changing the number of support arms and, lastly, adjusting their horizontal spacing.

Lengths (mm)

- 700mm

- 900mm

- 1200mm

- 1500mm

Capacities (kg)

The maximum cantilever shelving arm capacities listed below as uniformly distributed loads (UDL) are based specifically on the arm length selected.

- 260kg

- 350kg

- 450kg

- 1000kg

- 1300kg

Finish

Orange enamel powder-coat paint finish to the Cantilever Rack arms for sale.

Design of Arms

The arms have a small slope of up to 5 degrees incorporated into their design. This slope goes upward slightly from the column end of the arm to the end or tip of the arm. Hence, this prevents products from sliding or rolling off the arm level. Spigots (see below) are an accessory that aids in this as well.

Arm Spigots

The Arm Spigot is a steel pin that is 150mm long. To explain, the spigots insert into pre-fabricated holes at the ends of the cantilever arms. They have a shoulder that holds a length of around 100mm of the pin proud above the arm surface. The arm spigot helps prevent stored products from sliding or rolling off the arm. In some situations, it may be advantageous to remove the spigots to get better access to the stored products. This accessory item is very easy to remove and replace in any position.

Connection of Arm to Column

Each arm ends with a U-shaped section that is welded almost perpendicular to it, sized to fit snugly around the width of each column. A hardened steel arm pin inserts through both sides of the U-shaped section and through the holes in the column.

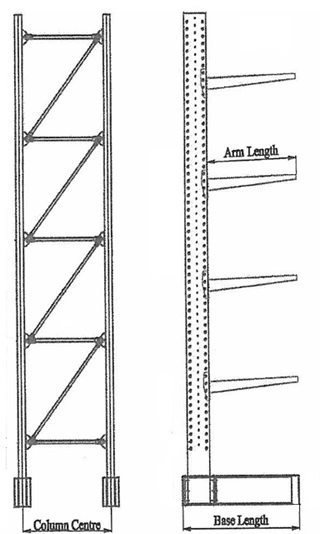

Cantilever Elevations

As an illustration, these two elevations of single-sided cantilever racking show bracing, arms, columns, and bases and how they interact with each other.

Front view (left)

Z-Shaped bracing pattern with both horizontal and diagonal bracing, brace to column fixing points, and column centre to centre dimension shown.

Side view (right)

Column with multiple arm fixing holes, arm to column attachment, column to base attachment, arm/base side view, plus arm/base dimensions shown.

c) Bases… supporting cantilever rack columns

High-strength bolts and nuts rigidly attach the bases to the bottom of the columns. This connection, between column and base, provides the front-to-back rigidity of the cantilever rack structure. Additionally, anchoring the structures to the ground (typically a concrete slab) reduces the risk of them toppling over.

Length of the Base

We determine the length of the single-sided cantilever rack column bases by adding the column depth to the longest arm length used on the column. Furthermore, for a double-sided cantilever rack, the arm length on the other side needs to be added in. Moreover, this dimension always slightly exceeds these combined measurements.

Assembly of the Base

Typically, a pair of ‘C’ section lengths makes up the bases, positioned on either side of the column. Their rigidity comes from tying the two sections together with bolts and nuts through the columns, along with a joiner plate at the free aisle-side ends.

Finish

Blue enamel powder-coat paint finish to the Cantilever Racking bases for sale.

Floor Anchors

Floor anchors fix the column bases to the concrete slab floor. They typically consist of either a screw anchor, mechanical anchors, or chemical anchors. Floor anchors are necessary to safely secure these structures and to reduce the chances of them toppling over.

d) Bracing… determines the column centres.

The bracing consists of horizontal and diagonal brace members. We place these brace members in a Z-shaped pattern between adjacent columns. Bracing fixed to the columns provides down-aisle rigidity to the cantilever storage racking structure. The column height dictates the number of Z-patterns required. The bracing lengths set the horizontal spacing between two adjacent columns (and two adjacent arms).

Column centres (mm)

- 900mm

- 1200mm

- 1500mm

- 1800mm

Finish

Blue enamel powder-coat paint finish to the Cantilever Rack bracing for sale.

Determining the column centre spacing required

Firstly, understanding the preferred horizontal spacing between arms for the stored product is important, as the product must not sag between arm spans. Determining the column centre spacing depends on the maximum horizontal spacing required between arms to suit the stiffness of the product. Once you understand the horizontal centre-to-centre spacing distance of arms and columns, you can select the brace lengths.

5. Products you can store in a cantilever rack

The typical use of cantilever warehouse racking is to store products that are too long for pallet racks, for example, and are not easily strapped to a single pallet. Suitable products will have some inherent rigidity, either individually or when strapped in pack form, that will suit a specific arm support spacing.

The reason why this is necessary is that the shelf level is not a continuous surface, as it consists of intermittent supports provided by a series of arms. It is important that the horizontal spacing between arms is close enough to prevent excessive sag or deflection over the individual spans.

Products typically found stored in cantilever storage rack systems include various items such as pipes, steel rods, tubing, conduit, extrusions (including metals such as aluminium and plastic), carpet rolls, timber lengths, timber crates, timber sheets, building materials, steel lengths, sheet metal, structural steel members, reinforcing bars, and other construction materials.

6. Configuring a Cantilever Rack System

Customising the size of this storage system to suit the available space in the storage facility is rather easy.

a) Length

The maximum product length stored has a direct bearing on the overall cantilever rack length. The two arms at the extreme ends of the product must both be explicitly providing support. Also, the rack must be long enough so that the product does not have an overhang on either side greater than half of the horizontal arm span.

To calculate the length of a cantilever rack, add the width of one column to the sum of the column centres. Hence, the sum of the column centres plus the column width equals the cantilever rack length.

b) Height

In this situation, the number of storage levels and the product height dictate the column height. Factoring in the height of the top arm storage level is also essential. Considering the height restrictions of the storage facility, it is a must to ensure that there is sufficient clear height above the highest product when placing and retrieving it from the top level.

c) Arm lengths

It is particularly important that the products stored do not overhang the end of the arm. Selecting the correct arm length is therefore quite important. The cantilever shelving arm length dictates the depth of products that may be stored on the level.

d) Arm capacities

Selecting the correct strength of the cantilever arms and columns is important to handle the maximum weight of the supported product. Both of these components directly impact the strength of the structure and the weight of the product stored on each level. Incidentally, column spacing directly influences the number of arms supporting the product.

e) Arm spacing vertically

Vertical spacing between arm levels is dependent firstly on the product height and secondly on the amount of product bowing. This is particularly important when lifting the product by forklift. With this in mind, ensure sufficient clearance for both the product itself and the bowing at the ends caused by the lifting action.

f) Strength Grades

Space Rescue has three different grades of structural cantilever racking systems for sale. These are specifically light-duty, medium-duty, and heavy-duty cantilever shelving. Undoubtedly, what differentiates one from the other is the size and strength of the columns, bracing, and arms used.

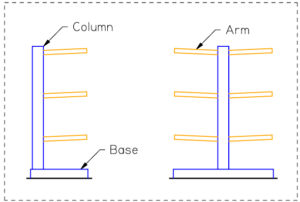

g) Types of Access

A single-sided cantilever racking structure (as shown below on the left) has arms on one side only. Positioning this structure against a wall is possible. The reason for this is that access is from one side only.

A double-sided cantilever racking structure (as shown below on the right) has arms on both sides of the same columns. Therefore, it is accessible from both sides.

Side Elevation of Cantilever Racking

Left sketch: single-sided configuration

Right sketch: double-sided configuration

7. Usage of Cantilever Racking

Usage

Cantilever Storage Rack usage is common in many industrial settings. For example, these include warehouses, factories, timber yards, and steel yards. It is especially important that a suitable concrete slab is available to support the loaded structures and to secure floor fixings into. The standard components described above are for indoor use only.

Finishes

The finish on a cantilever shelving system varies depending not only on the intended use but also the environment. By comparison, enamel powder-coat paint is the most common finish, providing durability and resistance to corrosion for internal applications. On the other hand, cantilever storage racking used in outdoor applications must have a hot-dipped galvanised finish, particularly to help prevent corrosion and rusting.

Forklift Use

The storage of heavy or bulky products will require a forklift, for example. Another reason for this would be if the rack was above two metres. In addition, forklift slippers help lift very long or wide products.

Load and Safety Signage

It is particularly important to fix load and safety signage to canti rack structures. To explain, this signage provides operators with an understanding of the maximum loads that can be placed on the structure.

Suitability of your floor

Firstly, you should install and secure cantilever shelving to a reinforced concrete slab that has sufficient strength and thickness. Secondly, Space Rescue takes no responsibility for the performance and suitability of the proposed floor or for assessing it. Similarly, Space Rescue is not responsible for the floor’s performance regarding structural performance under load or its ability to remain level and plumb as the load increases due to slab deflection. However, we are happy to provide information to help you determine the suitability of the proposed floor. However, we are happy to try and help you with the provision of information necessary for you to determine the suitability of the floor proposed.

8. Industrial Pipe Racking

Industrial pipe racking obviously stores various types of pipe. Typically, the arms will include a spigot at the ends to help prevent product from rolling off the arms.

9. FAQ

Yes, we highly recommend using appropriate floor anchors to secure our cantilever storage racks to an approved concrete slab of sufficient strength and thickness. Anchoring is important for front-to-back stability and to ensure the proper functioning of spine bracing for side-to-side or down aisle stability.

Our professional installers, dressed in personal protective equipment (PPE) and using both lifting and height access equipment, will make use of cantilever shelving installation manuals to undertake this serious task. In summary, they will first attach columns to bases, then stand and anchor this pairing to the floor in braced modules before attaching arms and safety load rating signage.

The applicable Cantilever Racking standard used for the design and manufacture of our Cantilever Storage Racking is FEM Code 10.2.09, ‘Design of Cantilever Racking’. This code outlines the principles for its design and the accompanying applicable requirements for all types of cantilever rack systems fabricated from steel members and intended for the static storage of unit loads.

Yes, we highly recommend that our cantilever racking system for sale be appropriately bolted down using our recommended floor anchors. This helps to minimise the risk of toppling over if it were to encounter any accidental horizontal forces from a forklift during loading, for example.

10. Availability of Cantilever Racking Systems for Sale

In addition to the variety of sizes of cantilever rack systems for sale, Space Rescue distributes cantilever racks to all corners of Australia, including regional areas and towns, all from our capital city warehouses.

Furthermore, you may also be interested in our pallet racking and storage compactors?